At PGT, our journey as a planetary gearbox manufacturer has always been about quality evolution and relentless pursuit of customer satisfaction. Not long ago, our gear production relied solely on the robust hobbing process—a proven method delivering reliable results but leaving room for surface refinement and better quality.

Customer feedback, demanding applications, and our own technical ambitions pushed us to question: how can we enhance precision further and offer gearboxes matching industry leaders? This question became the catalyst for a process transformation at PGT.

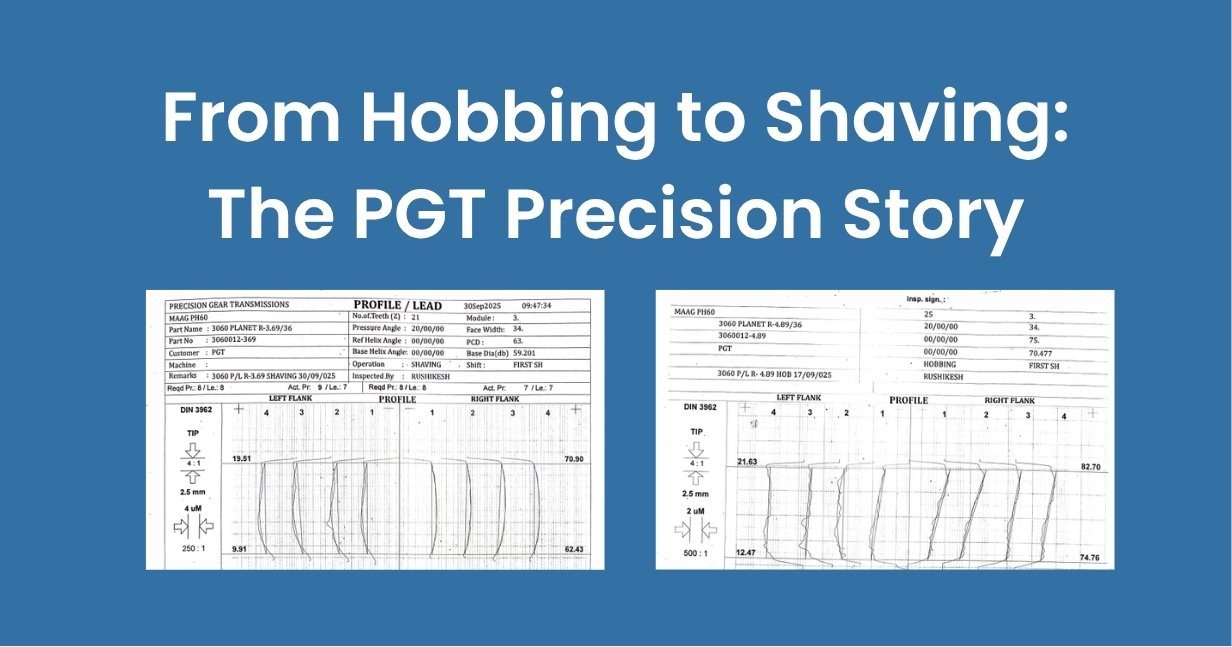

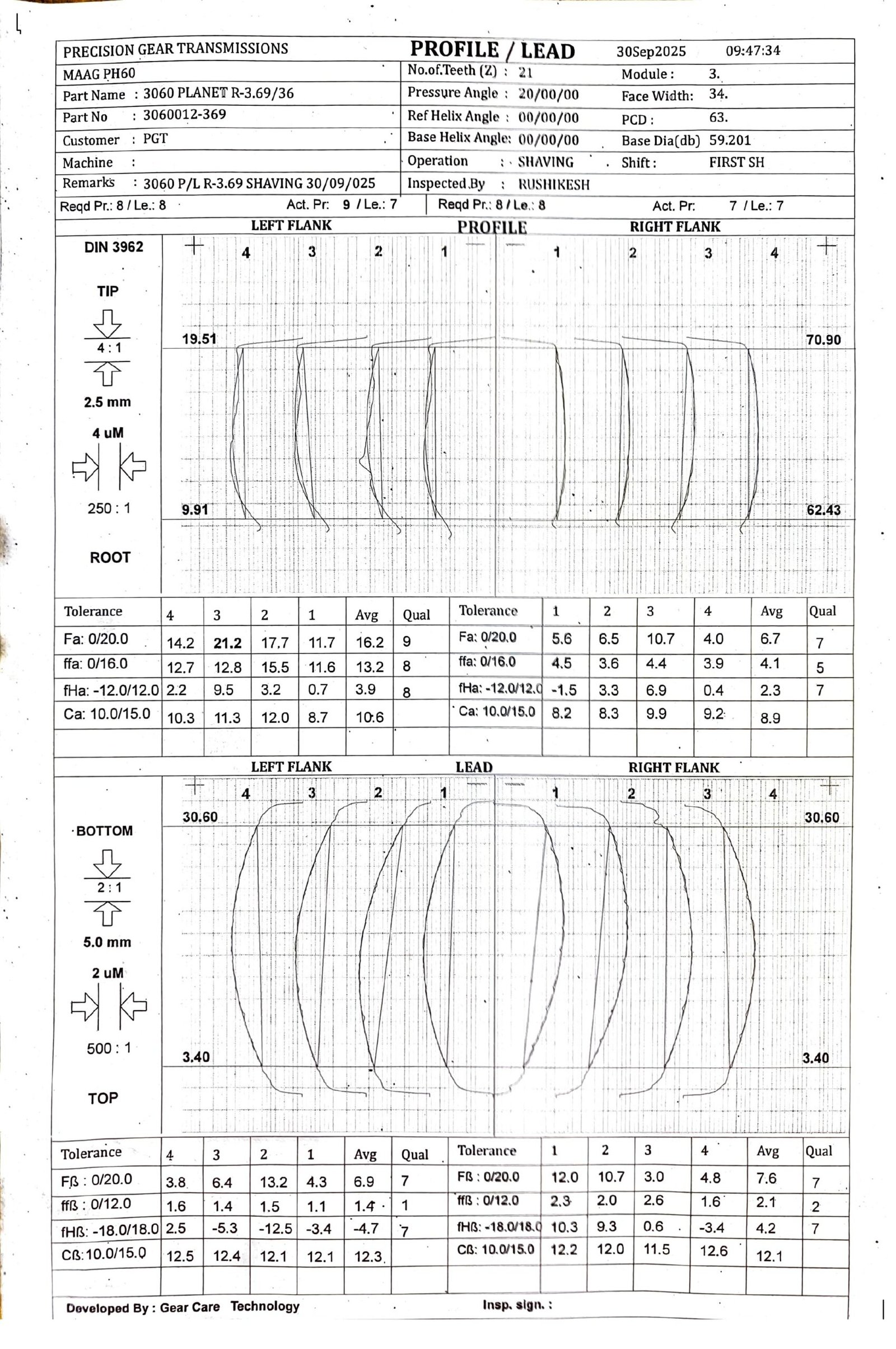

Our engineering team took a hard look at the lead profile reports. Hobbing delivered profile and lead tolerances within DIN 3962 Grade 7–8 (Fa, ffa, flHa, FS values often 7 to 12 μm), ensuring functional gears but with micro-roughness and occasional deviations at the tooth root and lead zone. For many, this would have been “good enough.”

Refusing to accept the status quo, PGT invested in shaving technology and integrated it post-hobbing. The difference was immediate and measurable. Our latest shaving reports show profile and lead tolerances regularly reduced to DIN Grades 6–7, with consistent surface finish improvements and average lead errors dropping to just 2–5 μm.

The impact?

Superior NVH performance, matching the standards of prominent industry players.

PGT’s story isn’t one of scale—it’s of mindset. While we may be smaller than some global gearbox brands, our commitment to world-class systems and meticulous process control stands shoulder-to-shoulder with the best in the industry.

PGT’s mission is clear: deliver better quality planetary gearboxes by learning, improving, and acting on every opportunity to delight our customers. Our journey from hobbing to shaving is just one chapter in our ongoing story of engineering excellence.

If you value partners who put quality above shortcuts and strive for progress with every gear delivered, PGT is ready to serve.

WhatsApp us